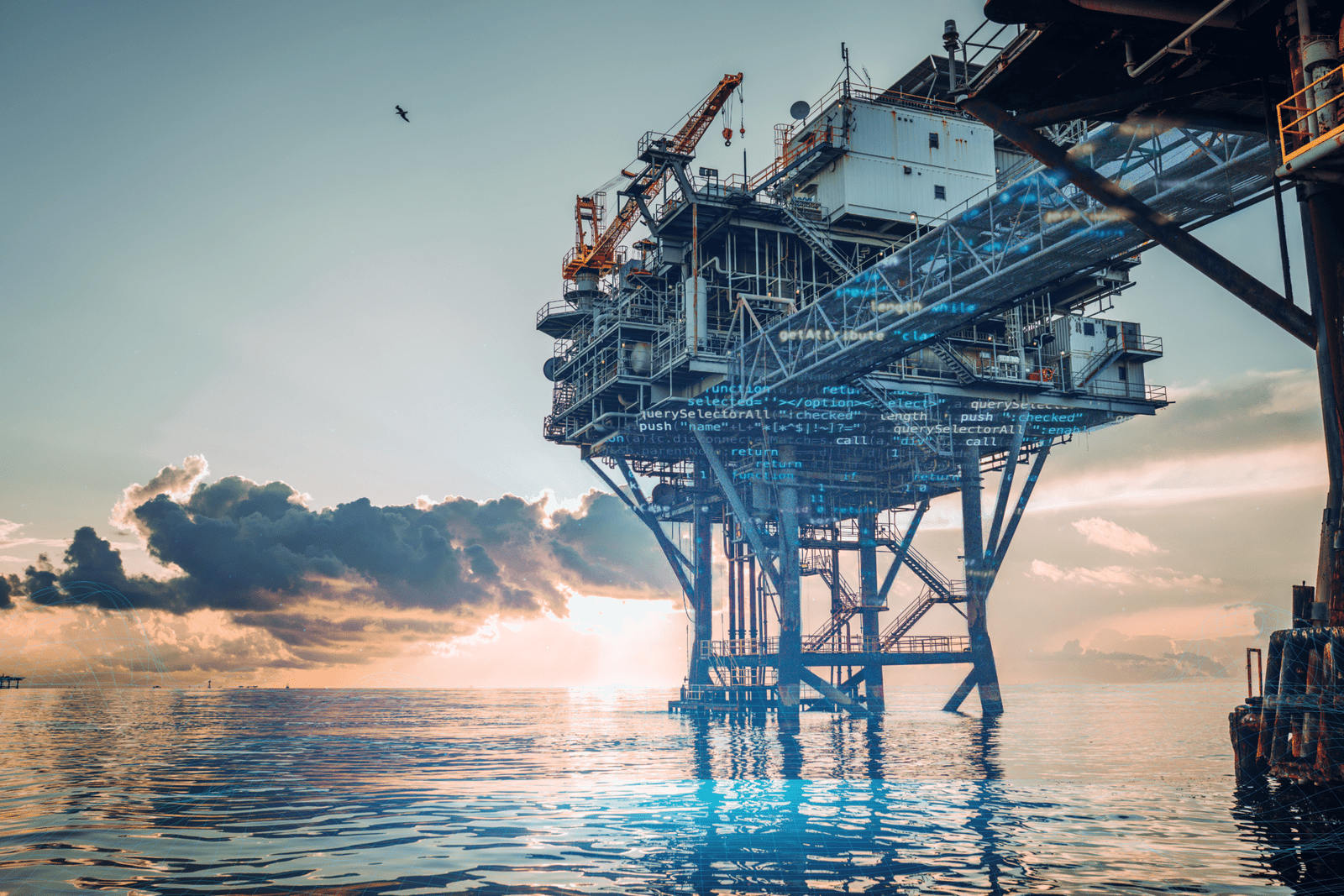

Applications of Digital Inclinometers in the Oil & Gas Industry

The oil and gas industry relies on precise measurements and monitoring systems to ensure safety, efficiency, and operational integrity. Among the emerging technologies that have made significant strides in this sector are digital inclinometers. These advanced devices provide critical data regarding the tilt and orientation of equipment and structures in various oil and gas applications, leading to improved operational performance and safety.

What are Digital Inclinometers?

digital inclinometers are highly sensitive devices that measure angles of slope (tilt) or orientation of machinery and structures. The digital aspect refers to the output being delivered in a digital format, making it easier to integrate with various monitoring systems and software applications.

Key Applications in the Oil & Gas Industry

1- Drilling Operations

In drilling, maintaining the correct wellbore angle is crucial for efficient extraction of resources. digital inclinometers are employed to monitor drill string inclinations in real-time, ensuring that the well trajectory remains within desired parameters. This capability not only enhances drilling efficiency but also minimizes the risk of drill bit failure and unexpected geological complications.

2-Wellbore Stability Monitoring

The integrity of a wellbore is vital to the success of exploration and production activities. inclinometers can detect minute changes in tilt, providing valuable data on wellbore stability. By continually monitoring these changes, operators can anticipate and mitigate potential collapse issues or other geological hazards, ultimately enhancing well safety and reducing costly downtime.

3-Production Equipment Monitoring

In production facilities, the alignment of exploration and extraction equipment, such as pumps, separators, and compressors, is essential for optimal performance. inclinometers help in ensuring that these machines are properly aligned. This alignment reduces wear and tear on equipment, increases efficiency, and prolongs their service life.

4-Structural Health Monitoring

Oil and gas facilities often comprise complex structures, such as platforms and pipelines, that are subjected to environmental stressors. Digital inclinometers can monitor structural integrity by measuring subtle changes in tilt or displacement over time. This data can be used to identify any potential structural failures before they escalate into significant safety hazards or operational disruptions.

5- Seismic Activity Monitoring

The oil and gas industry are often vulnerable to seismic events. Implementing digital inclinometers allows for the continued monitoring of

ground movements and vibrations that may indicate seismic activity. This data provides operators with the information needed to make informed decisions regarding operations in potentially hazardous conditions, ensuring worker safety and asset protection.

6- Geotechnical Applications

In geotechnical evaluations, monitoring the soil and rock behavior around drilling sites is critical. inclinometers are used to assess slope stability by measuring inclinations in the surrounding geological formations. This information can guide well placement and mitigate risks associated with landslides or subsidence, particularly in sensitive areas.

7- Environmental Monitoring

Environmental compliance is essential in the oil and gas industry. inclinometers can be deployed to monitor slopes in areas adjacent to drilling sites or pipelines, helping to ensure that operations do not adversely impact the surrounding environment. This proactive approach not only ensures compliance with environmental regulations but also enhances community relations.

Conclusion

The integration of digital inclinometers into the oil and gas industry represents a significant technological advancement, enabling operators to obtain real-time, accurate measurements that enhance operational safety and efficiency. By addressing critical aspects such as drilling performance, structural integrity, and environmental monitoring, these sensors contribute to more reliable and cost-effective operations. As the oil and gas sector continues to explore innovative technological solutions, inclinometers will undoubtedly play an increasingly vital role in ensuring safe and efficient extraction of resources in the years to come.